What is Kanban Inventory Management?

Posted by Jill Glen on 21st Feb 2023

At Diamond Industrial, we offer several different services designed to make our customers’ lives easier. One of the most popular amongst our manufacturing clients is our Kanban Inventory Management service. Honestly, this is one of those things which sounds a lot more complicated than it is – so we thought we’d write a quick article to help you decide if it’s a service that could help your business.

What is Kanban?

Kanban was developed as a system for controlling the flow of materials within a supply chain to reduce waste. Kanban just means “billboard” or “visual sign.”

The Kanban system works best with systems that require a constant amount of small parts and run a continuous production line. It is a rolling two-bin system that provides your team with the supplies they need at the right time in the right place.

Sound good? It gets better – the simple inventory system, managed by our Kanban team, takes away time and stress from you and ensures that you are never short of anything, and you don’t need to hoard more stock than you need.

So how does it work?

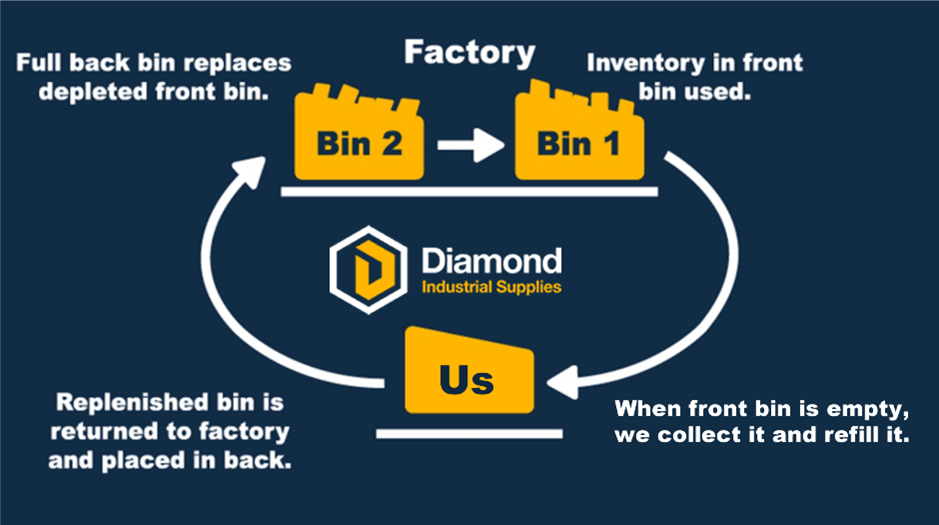

Here’s a little diagram which explains the system in the easiest way we know how:

Our team will visit your premises on a regular basis to refill

the empty bins as the new bins are brought forward ensuring inventory levels

are always kept up to date. This allows

stock levels to be considerably reduced compared with classic inventory

management.

We will work with you to analyse the current use of inventory to ensure that

the system works for you and your needs as a business.

What will it do for me?

Our Kanban system will allow you to streamline your systems in order to significantly improve production performance, delivering exactly what you need when you need it. With a reduced supplier base and minimal inventory, our customers are able to make their systems lean and agile.

Using visual signals (empty bin) Kanban controls inventory by pulling supplies (full bin) to the production floor based on demand. This has lots of benefits including:

- Reduced inventory

Since parts are not delivered until just before they are needed, you don’t need to waste time and warehouse space on excess stock.

- No more obsolete stock

If you no longer need a part, or you upgrade to a different component, you are not left with stock of something you no longer need.

- Increases Flexibility

If there is a drop in demand or a contract changes you aren’t left with extra inventory which allows for more flexibility in production lines.

- Increases Output

Since the flow of inventory speeds up and slows down as you use it, your stock of components will never be a bottleneck again.

- Reduces Total Cost

As well as reducing your inventory cost, and improving your overall production speed, our Kanban Inventory System will help to reduce waste and improve your overall business flow.

If you think that Kanban Inventory Management would help to improve your business, get in touch with Diamond Industrial Supplies today.